A Comprehensive Guide to One-Stop Eyeglass Factory Operations

Comprehensive Eyeglass Factory: Unparalleled Manufacturing Excellence in Titanium Eyewear Production

At Comprehensive Eyeglass Factory, we pride ourselves on being a global leader in high-volume eyeglass manufacturing, specializing in premium materials like Titanium and innovative designs such as the Scalp™ series. With decades of expertise, our Comprehensive Eyeglass production facility combines cutting-edge technology with rigorous quality control to deliver millions of frames annually, catering to brands worldwide.

1. Unmatched Production Capacity

As a Comprehensive Eyeglass Factory, our vertically integrated facility spans 50,000+ square meters, housing 20+ automated production lines dedicated to eyeglass manufacturing. Key highlights include:

Titanium Expertise: Specialized workshops for Titanium frame processing, leveraging laser welding and CNC precision machining to produce lightweight, hypoallergenic frames.

Scalp™ Technology: Proprietary Scalp™ surface treatment enhances durability and aesthetics, offering scratch-resistant finishes for collections like River and Mount.

Daily Output: 50,000+ eyeglass units, with a monthly capacity exceeding 1.5 million frames.

Our Comprehensive Eyeglass operations are designed for scalability, ensuring seamless order fulfillment even during peak demand.

2. Advanced Manufacturing Technologies

The Comprehensive Eyeglass Factory invests heavily in innovation:

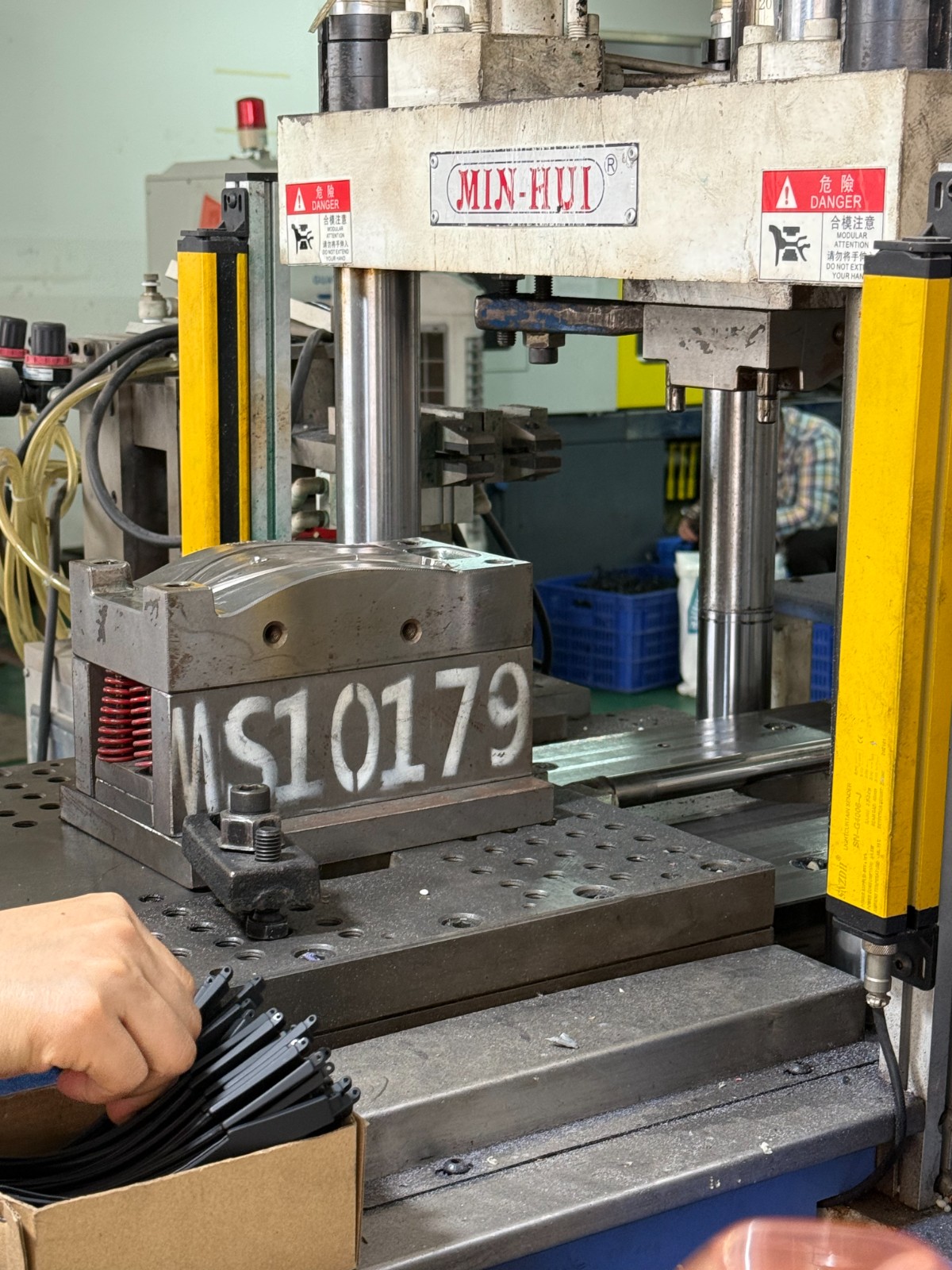

Automated Assembly: Robotics-assisted production lines ensure consistent quality across Titanium and acetate frames.

3D Printing: Rapid prototyping for designs like Mount (adventure series) and River (minimalist line), reducing R&D cycles by 40%.

AI Quality Control: Computer vision systems inspect every eyeglass frame for defects, achieving a 99.8% pass rate.

By integrating these technologies, our Comprehensive Eyeglass facility maintains ISO 9001 and CE certifications, meeting international standards.

3. Global Supply Chain & Logistics

Strategically located near major ports, our Comprehensive Eyeglass Factory ensures efficient global distribution:

Raw Material Sourcing: Direct partnerships with Titanium suppliers in Japan and Germany for grade-5 alloy.

Warehousing: 10,000+ pallet spaces for eyeglass inventory, supporting just-in-time deliveries.

Shipping: 100+ containers shipped monthly to North America, Europe, and Asia, with OEM/ODM services for brands.

4. Sustainable & Customizable Production

Sustainability is core to our Comprehensive Eyeglass ethos:

Eco-Friendly Processes: Water recycling systems and solar-powered units reduce carbon footprint.

Custom Solutions: Tailored Titanium finishes (e.g., matte Scalp™ coating) and flexible MOQs for startups to Fortune 500 clients.

Why Choose Comprehensive Eyeglass Factory?

Scale: Among the top 5 eyeglass manufacturers globally by volume.

Quality: Titanium frames tested for 10,000+ flex cycles.

Innovation: Patented Scalp™ technology for premium collections.

Partner with us to leverage the power of a truly Comprehensive Eyeglass production hub. Contact our team today for a factory tour or quote!