Our eyewear factory is equipped with world-class production equipment, leveraging cutting-edge manufacturing technologies and highly automated processes to ensure that every pair of glasses meets international quality standards. The factory is outfitted with high-precision CNC machines, fully automated coating systems, and multifunctional inspection instruments. These advanced tools not only enhance production efficiency but also ensure exceptional consistency and precision across all stages of manufacturing. From frame cutting and polishing to lens processing and coating, our production process is highly automated, allowing us to maintain strict control over every detail.

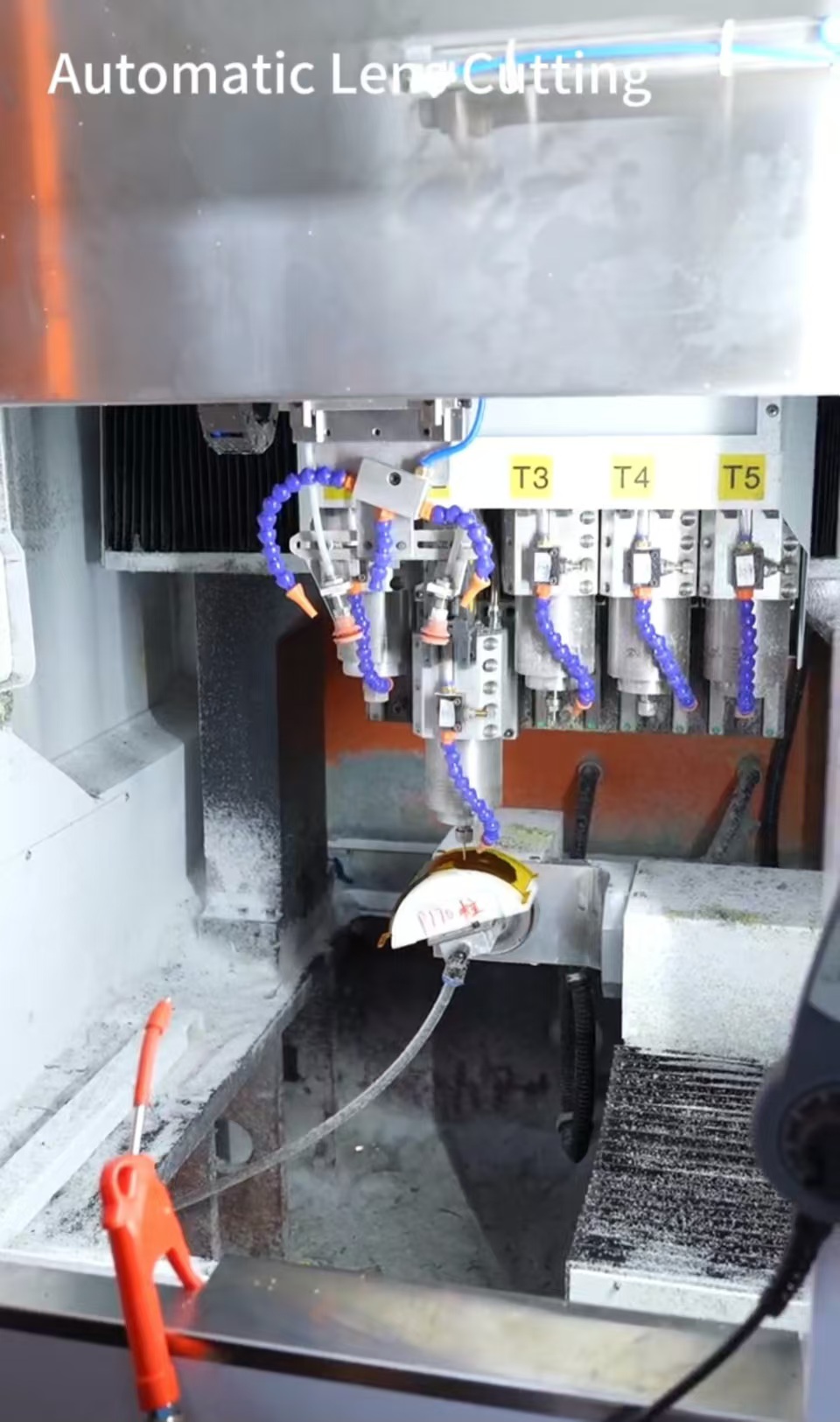

In the frame production process, our high-precision CNC machines perform intricate cutting, shaping, and polishing with remarkable accuracy. These machines can handle a variety of materials, from metal and plastic to composite materials, delivering frame designs with flawless aesthetics and structural integrity. CNC technology ensures that every frame is crafted to perfection, with minimal deviations, ensuring both visual appeal and comfort. This level of precision not only enhances the quality of each individual frame but also increases production speed, allowing us to meet the demands of large-scale orders without compromising on quality.

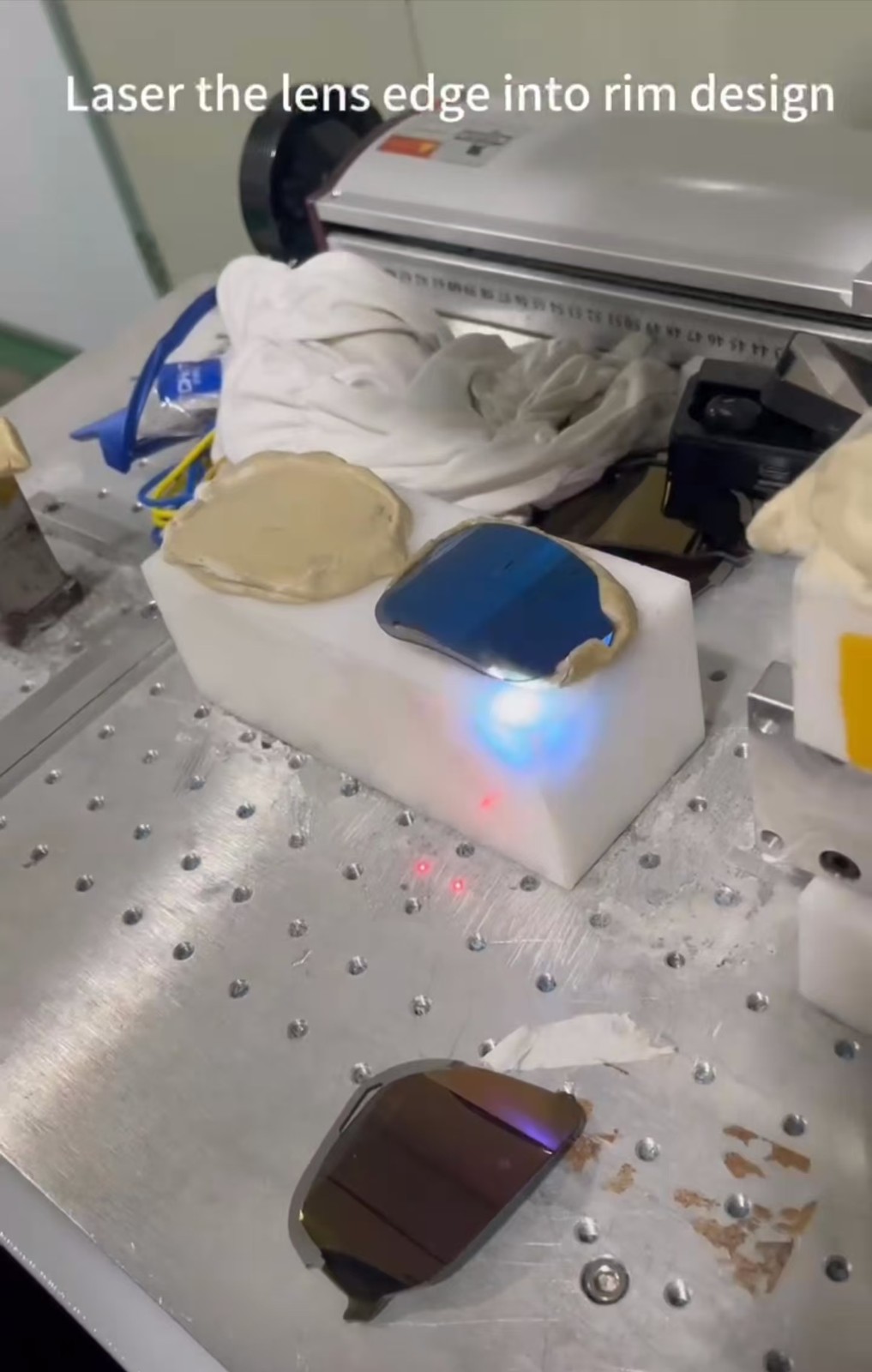

When it comes to lens processing, our fully automated coating systems ensure that every lens receives the optimal surface treatment. Through automated processes, lenses are equipped with advanced coatings such as anti-reflective, UV protection, and anti-smudge layers. These coatings significantly enhance the durability of the lenses and improve the overall visual experience for the wearer. By using automated technology, we guarantee uniformity in the coating application, eliminating the inconsistencies that can arise from manual methods. This results in lenses that not only meet the highest quality standards but also provide long-lasting performance.

Our factory also features multifunctional inspection instruments capable of analyzing both optical and mechanical properties of lenses and frames. These instruments perform comprehensive evaluations, ensuring that every product meets strict criteria for optical clarity, pressure resistance, and abrasion durability. The data collected from these inspections allows us to ensure that every pair of glasses leaving our factory complies with, or exceeds, international quality standards. Before any product reaches the market, it undergoes a series of rigorous tests, confirming its visual accuracy, strength, and overall comfort.

Our technical team, composed of experienced and innovative professionals, is constantly pushing the boundaries of production technology. They focus on streamlining processes, reducing production times, and cutting costs without compromising the high standards we uphold. By continually refining our manufacturing methods, we deliver products that are not only superior in quality but also highly competitive in the marketplace. Beyond improving existing processes, our team is always exploring new materials and technologies, ensuring we stay at the forefront of the industry and meet the evolving demands for high-end, customized eyewear products.

With these advanced production techniques and innovative technologies, our factory is capable of handling a wide range of orders, from large-scale mass production to specialized custom designs. Whether it's precision cutting and polishing or fully automated coating and inspection, we ensure that every pair of glasses is an exact reflection of the design specifications, maintaining consistency and exceptional quality across the board. This integration of technology and efficiency has earned our products a strong reputation for meeting international standards and exceeding customer expectations in global markets.

It is through this commitment to advanced production techniques and continuous innovation that our factory consistently delivers superior and competitive eyewear products, creating significant value for our clients worldwide.