The journey of a pair of acetate eyewear from a factory workbench to a ret

ail display is a meticulous ballet of craftsmanship, quality control, and logistical precision. In an industry where aesthetics are paramount and first impressions are everything, the final stages of fulfillment—particularly the handling of the Acetate Case, the precise Pairing Glasses with Case, the complexities of Mixed Packaging, the structural integrity of the Integral Temple, and the fundamental Check case for closure integrity—are not merely procedural steps but critical brand-defining actions. This 2500-word exploration delves into how these specific elements converge to define excellence in the premium eyewear shipping process.

Part 1: The Core Elements of Premium Eyewear Fulfillment

1.1 The Integral Temple: The Foundation of Acetate Quality

Acetate, a plant-based plastic derived from cotton fibers, is celebrated for its rich colors, depth, and hypoallergenic properties. Unlike metal frames with screwed-on temples, a hallmark of quality acetate frames is the Integral Temple. This means the temple is carved from the same solid piece of acetate as the front of the frame, offering seamless aesthetics and superior durability without weak solder or weld points.

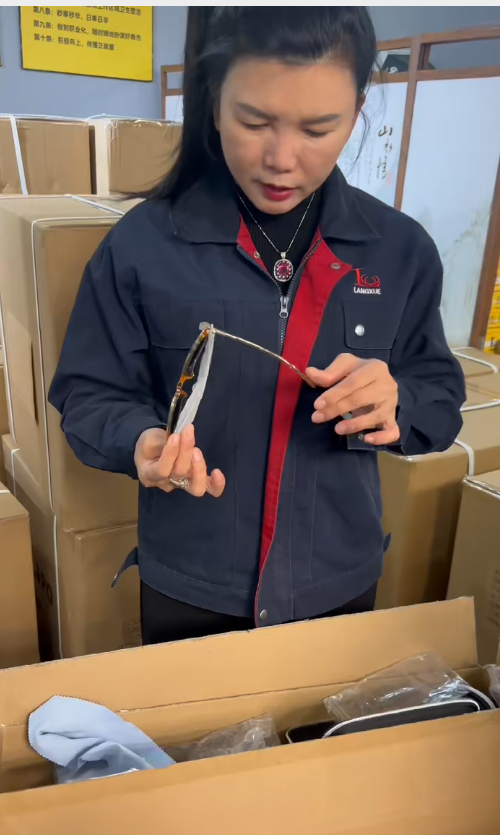

However, this construction presents unique inspection challenges. During Shipping Inspection, the Integral Temple is a critical focus area. Inspectors perform a Visual Inspection for stress marks—fine, hairline cracks that can appear near the hinge area due to molding stress or improper handling. They also check for perfect symmetry; a warped Integral Temple can cause the glasses to sit unevenly on the wearer’s face, leading to discomfort and a clear product failure. The flexibility test is crucial: the temple must have a consistent, spring-like flex without any creaking sounds or signs of brittleness. Every Integral Temple must be polished to a flawless, glass-like finish, free from milling marks or dull patches, ensuring the premium feel justifies the price point.

1.2 The Acetate Case: More Than Just a Container

The Acetate Case is the first tangible touchpoint a customer has with the brand upon unboxing. For premium acetate eyewear, the case is often a product in itself, frequently crafted from a thinner-gauge acetate that complements or matches the frame’s color and pattern. Its role is dual: protection and brand elevation.

The quality control for an Acetate Case is rigorous. A core step is the Check case for closure integrity. This involves repeated open-close cycles to test the hinge or magnetic closure for smooth operation and secure hold. A weak magnet or a misaligned snap closure can render the case useless, exposing the glasses to damage. Inspectors also examine the interior microsuede or velvet lining for flawless adhesion and the absence of glue stains or loose threads that could scratch lenses. The exterior finish is scrutinized for the same high-gloss polish and color consistency as the glasses themselves. A mismatched or poorly finished case immediately diminishes the perceived value of the entire product.